Luckily, this radio came equipped with a switched phono jack that leads directly to the volume control. Plugging into this jack disconnects the audio amplifier from the reciever section of the radio and switches in whatever signal is sent through the jack. This means I don't even need to add a switch, I can just send a small length of cable out the back of the radio from the bluetooth module inside.

Luckily, this radio came equipped with a switched phono jack that leads directly to the volume control. Plugging into this jack disconnects the audio amplifier from the reciever section of the radio and switches in whatever signal is sent through the jack. This means I don't even need to add a switch, I can just send a small length of cable out the back of the radio from the bluetooth module inside.

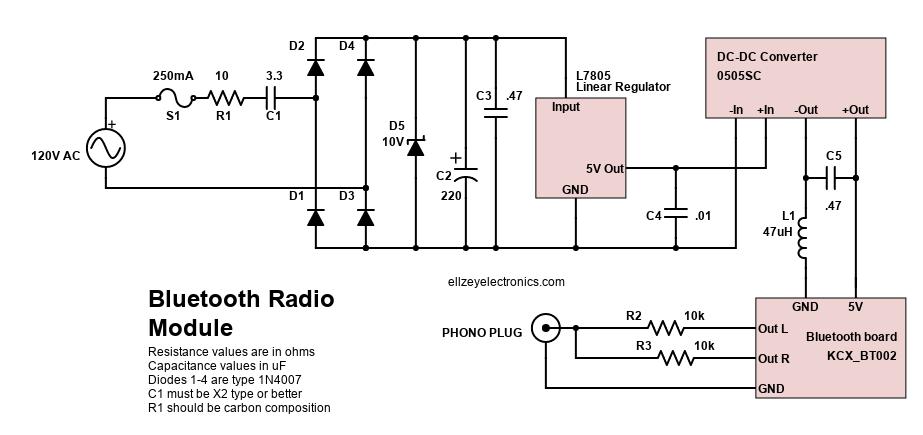

This is the circuit I ended up with. It's a capacitive dropper that can put out around 80 mA. The AC is dropped by the impedance of C1, rectified, and sent to a linear regulator. Then, to avoid noise from ground loops, a DC-DC converter provides the bluetooth board with an isolated 5V. R1 is there to tame spikes. D5 ensures that the regulator only sees 10V max. C3, C4, C5, and L1 are chosen based on the datasheets of the active components. Lastly, the output from the bluetooth is summed to mono and sent to the phono input of the radio through R2 and R3.

This is the circuit I ended up with. It's a capacitive dropper that can put out around 80 mA. The AC is dropped by the impedance of C1, rectified, and sent to a linear regulator. Then, to avoid noise from ground loops, a DC-DC converter provides the bluetooth board with an isolated 5V. R1 is there to tame spikes. D5 ensures that the regulator only sees 10V max. C3, C4, C5, and L1 are chosen based on the datasheets of the active components. Lastly, the output from the bluetooth is summed to mono and sent to the phono input of the radio through R2 and R3.

My initial research of capacitive droppers led me to believe that C1 must be a safety capacitor but I don't think that would actually make the circuit safer in this case. Since an X rated capacitor would likely fail short, the low voltage side could get the full brunt of the wall voltage and destroy itself before the fuse even blows.

(Please know that this circuit is inherently dangerous. Like the radio, the power supply has no isolation so if you do attempt this circuit, do so at your own risk and please do your research before attempting to work with mains voltage.)

A better option for C1 is a regular poly-film capacitor with a high voltage rating (at least 3 times wall voltage). This is a picture of the insides of a Mr. Coffee machine that uses a very similar circuit to power the low voltage electronics. It uses a 1.5 uF cap that is rated at 400V and I'll be using five .47 uF 630V capacitors in parallel because that's what I had in my droor.

A better option for C1 is a regular poly-film capacitor with a high voltage rating (at least 3 times wall voltage). This is a picture of the insides of a Mr. Coffee machine that uses a very similar circuit to power the low voltage electronics. It uses a 1.5 uF cap that is rated at 400V and I'll be using five .47 uF 630V capacitors in parallel because that's what I had in my droor.

I first built the circuit on a breadboard to verify that it worked. I used a dummy load resistor to simulate the current draw and then replaced it with the actual bluetooth board.

I first built the circuit on a breadboard to verify that it worked. I used a dummy load resistor to simulate the current draw and then replaced it with the actual bluetooth board.

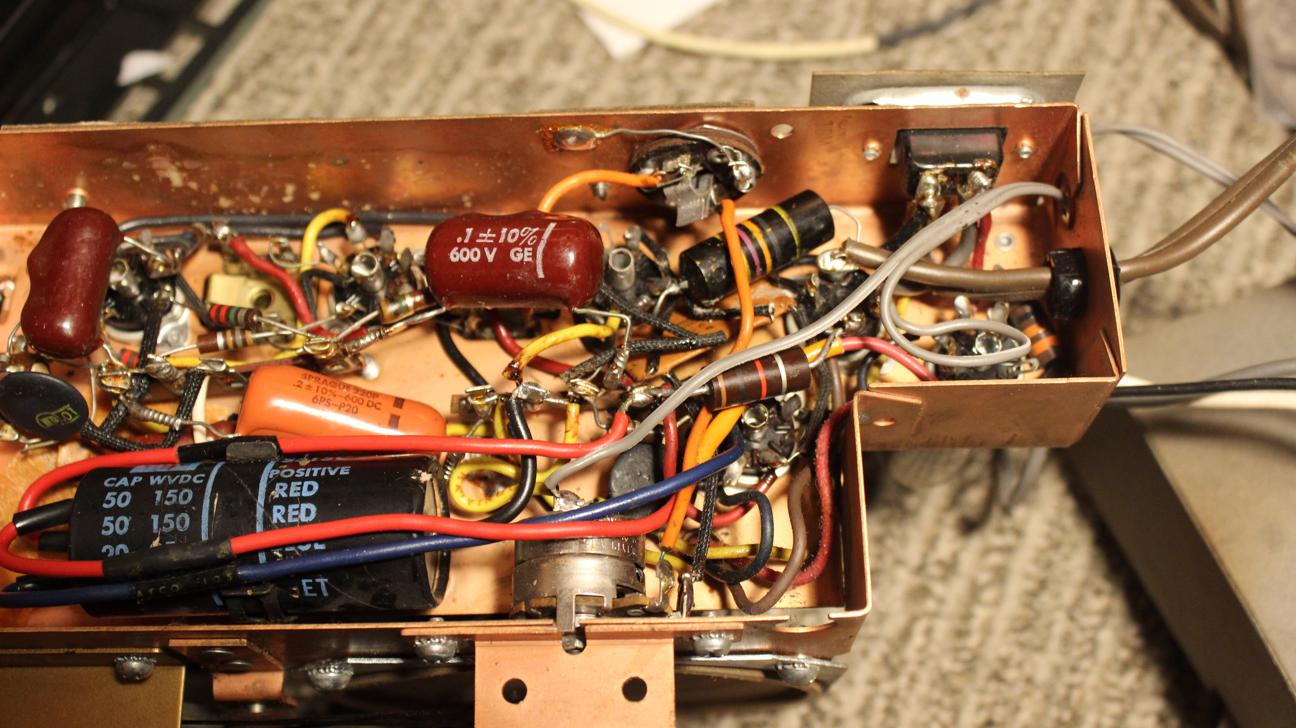

To provide the power, I soldered grey lamp cord to the switch and AC input and sent it through a hole in the chassis that just happened to be there already. That big bumblebee cap in the background was later removed. It was soldered across the line which is a bad place for an antique paper foil cap. All the other capacitors in the radio were upgraded to poly film types and the electrolytics were replaced.

To provide the power, I soldered grey lamp cord to the switch and AC input and sent it through a hole in the chassis that just happened to be there already. That big bumblebee cap in the background was later removed. It was soldered across the line which is a bad place for an antique paper foil cap. All the other capacitors in the radio were upgraded to poly film types and the electrolytics were replaced.

I wanted to make sure the radio was in good shape before putting everything back together so I started working on the plastic case with some epoxy. Here I used the resin to fill in where the plastic broke off.

I wanted to make sure the radio was in good shape before putting everything back together so I started working on the plastic case with some epoxy. Here I used the resin to fill in where the plastic broke off.

There was also a huge crack that needed to be fixed before anything could be put back in the case.

There was also a huge crack that needed to be fixed before anything could be put back in the case.

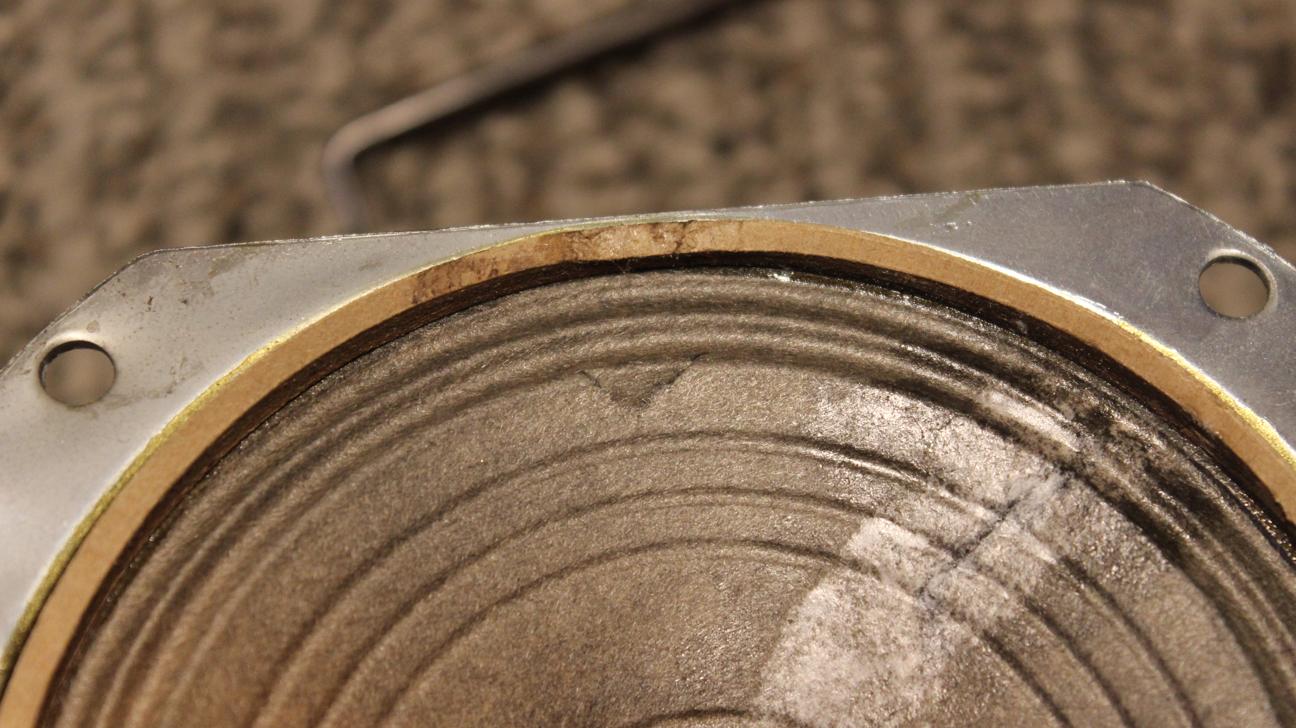

The speaker was ripped in a couple places. This can be fixed with a little PVA glue and tissue paper.

The speaker was ripped in a couple places. This can be fixed with a little PVA glue and tissue paper.

After the repair. This method provides a sturdy and flexible bond and works better than any other method I've tried for paper cones.

After the repair. This method provides a sturdy and flexible bond and works better than any other method I've tried for paper cones.

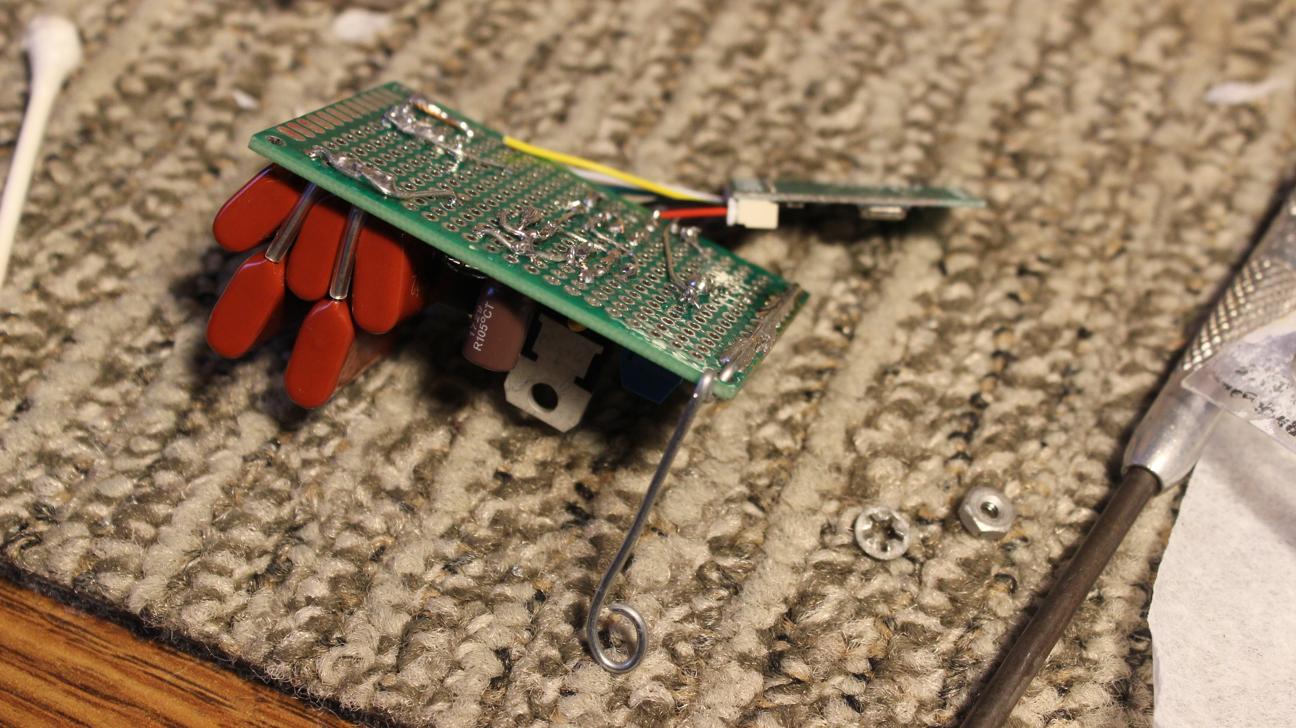

Here is the prototype board all put together. I didn't have any fuse holders so I had to improvise.

Here is the prototype board all put together. I didn't have any fuse holders so I had to improvise.

I soldered the bluetooth leads directly into the board and used terminal screws for the other connections.

I soldered the bluetooth leads directly into the board and used terminal screws for the other connections.

Testing the board with power from the radio

Testing the board with power from the radio

To mount it inside, I made a bracket out of steel wire to hook onto an existing mounting screw on the clock assembly.

To mount it inside, I made a bracket out of steel wire to hook onto an existing mounting screw on the clock assembly.

This way it would take up minimal space and be the furthest from the heat-generating tubes.

This way it would take up minimal space and be the furthest from the heat-generating tubes.

New plug soldered on. The right angle plug turned out to be too shallow to reach the jack so I went with the straight style.

New plug soldered on. The right angle plug turned out to be too shallow to reach the jack so I went with the straight style.

Now it's ready to go. At the end of this project, no changes were made to the radio at all. The next step is to make PCB's to allow me to repeat this upgrade in the future.

Now it's ready to go. At the end of this project, no changes were made to the radio at all. The next step is to make PCB's to allow me to repeat this upgrade in the future.