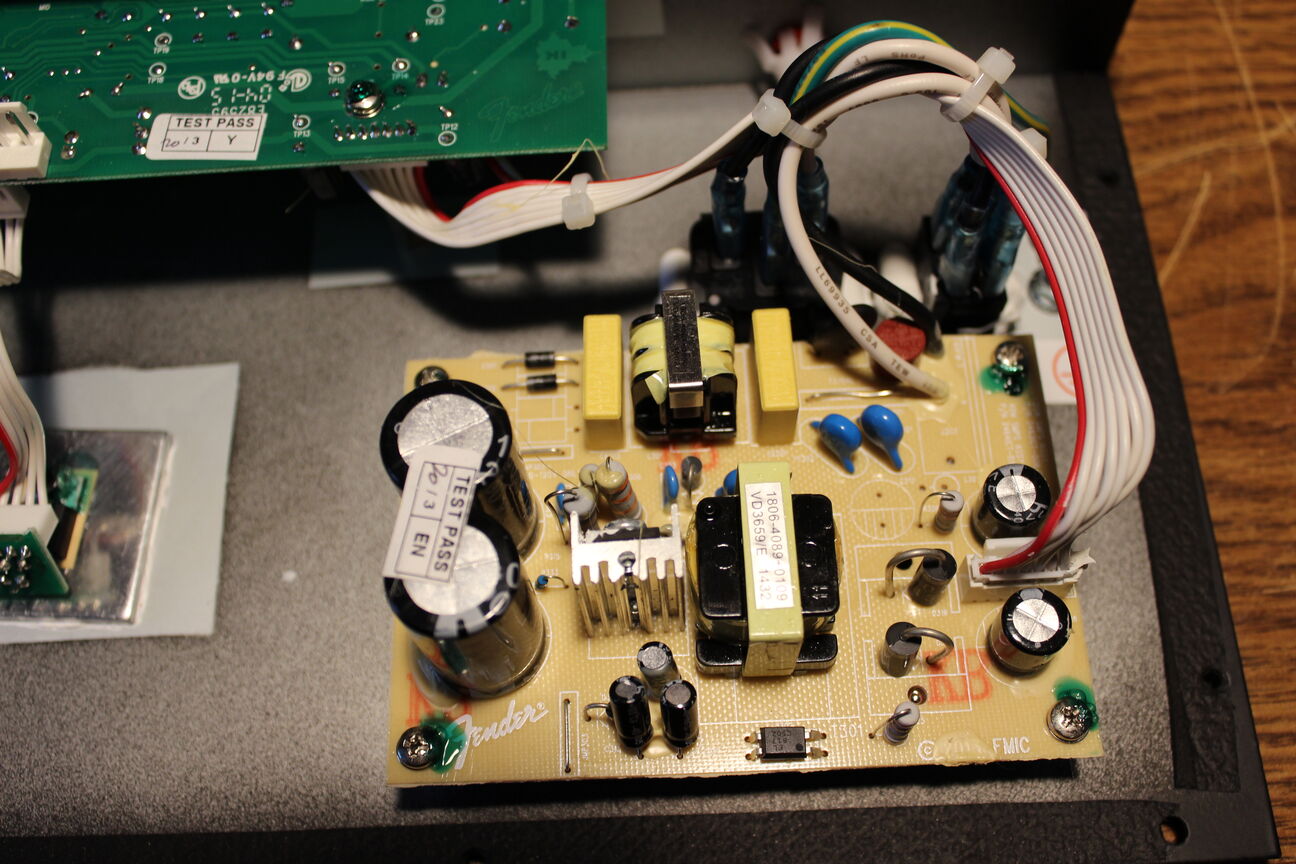

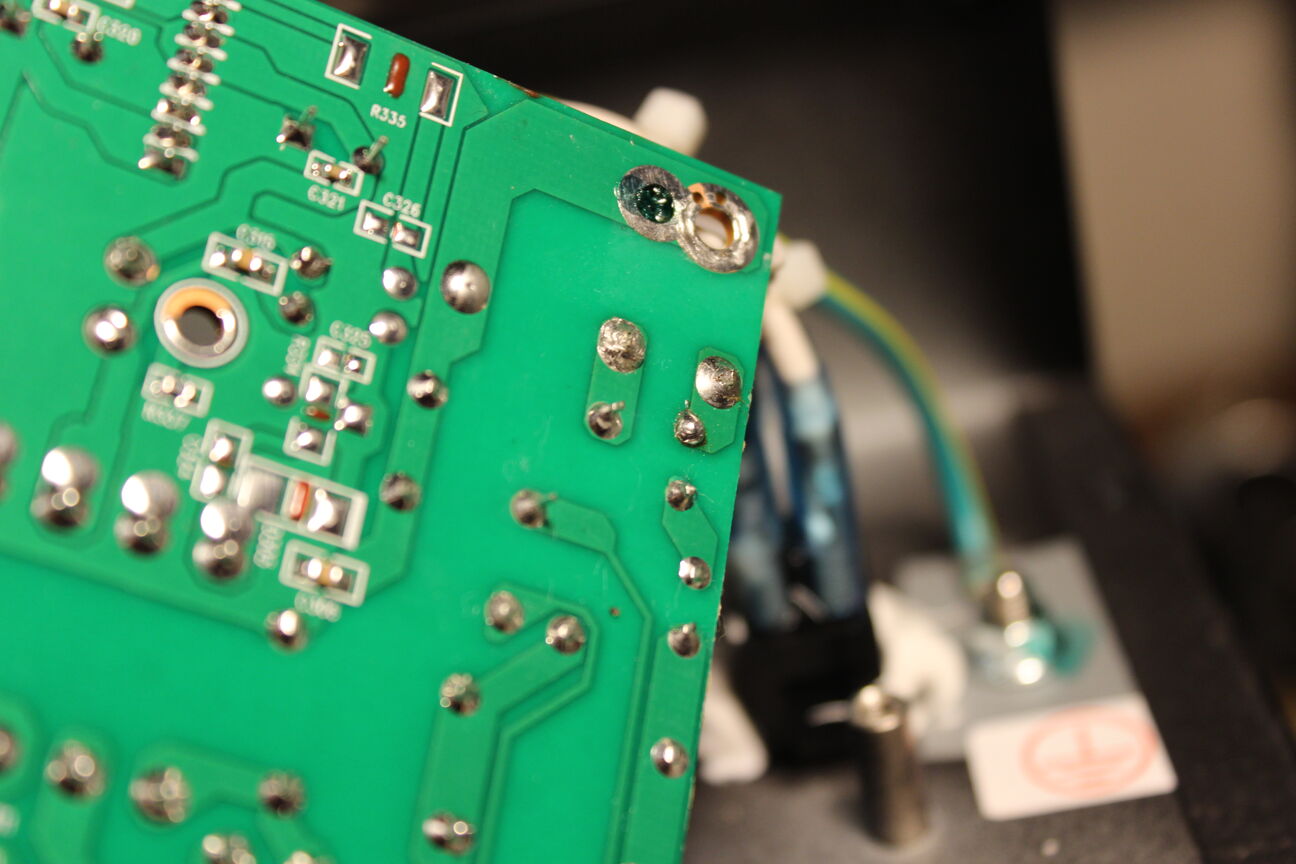

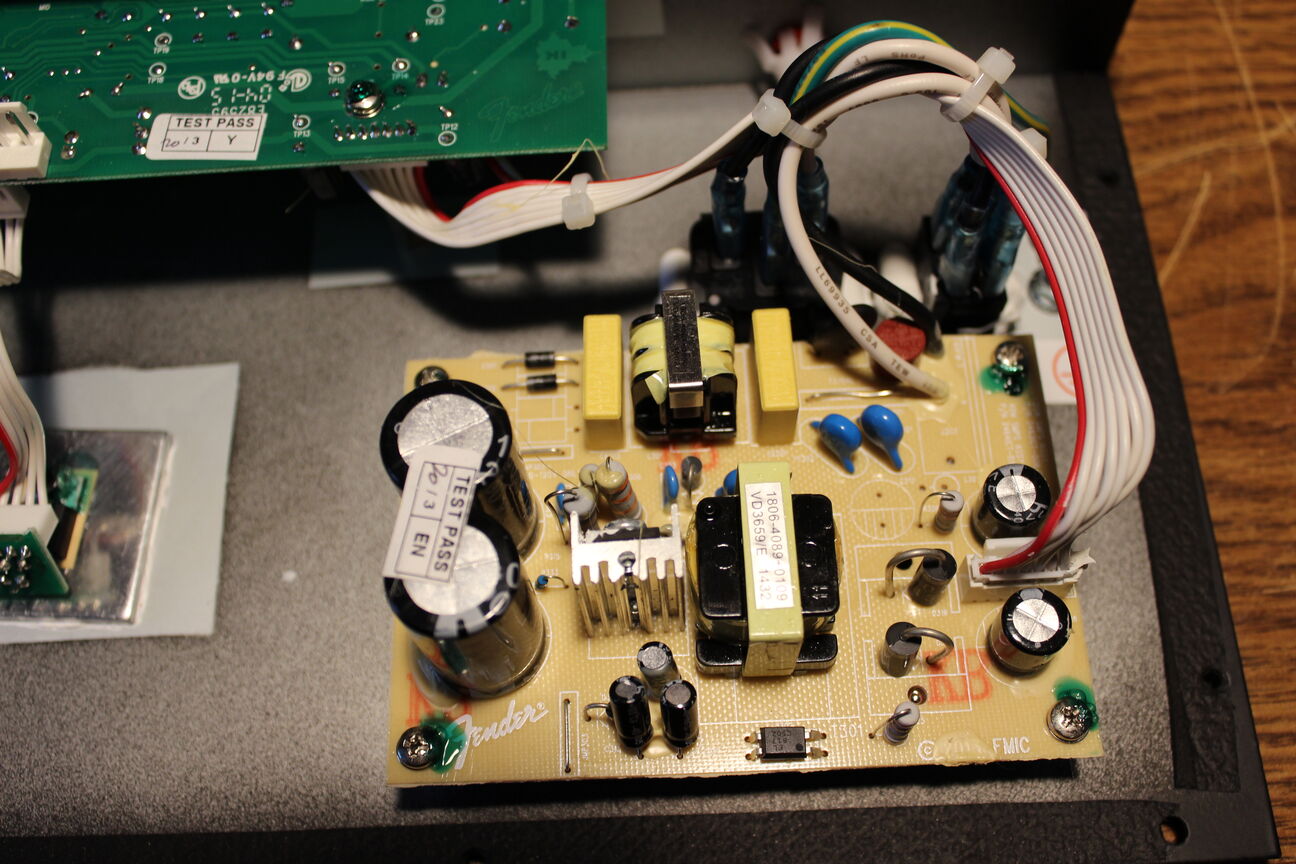

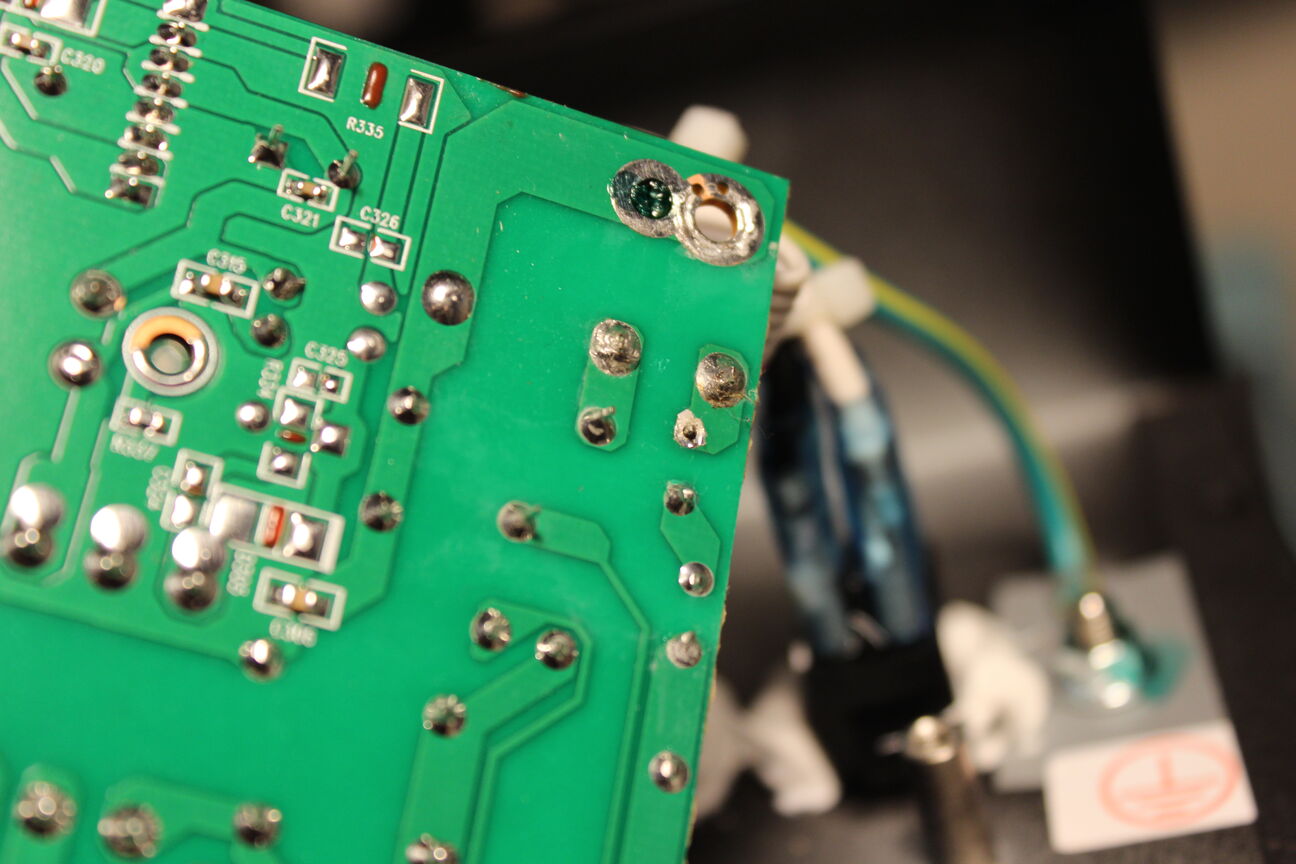

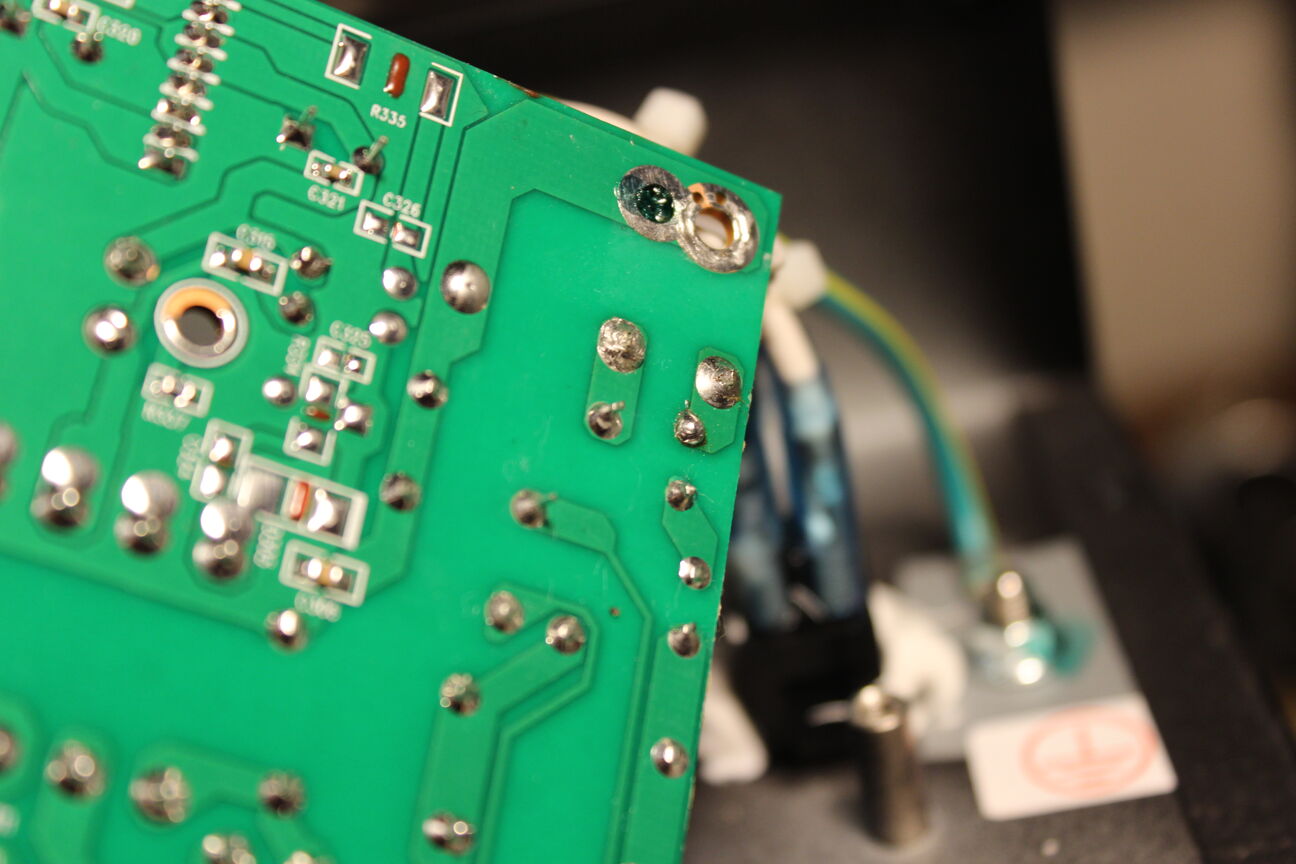

First I checked the power supply board for any burnt looking components but everything looked normal.

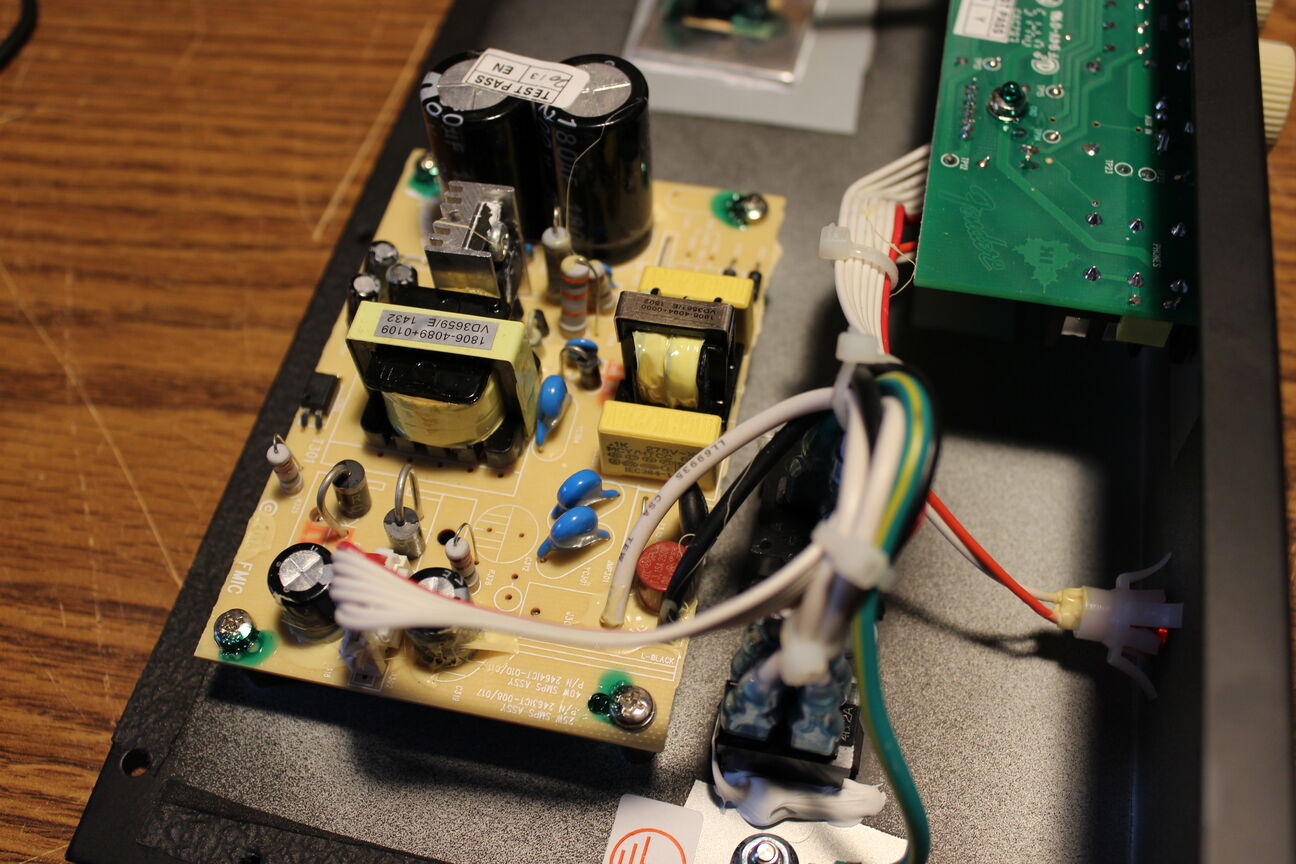

Another shot of the board

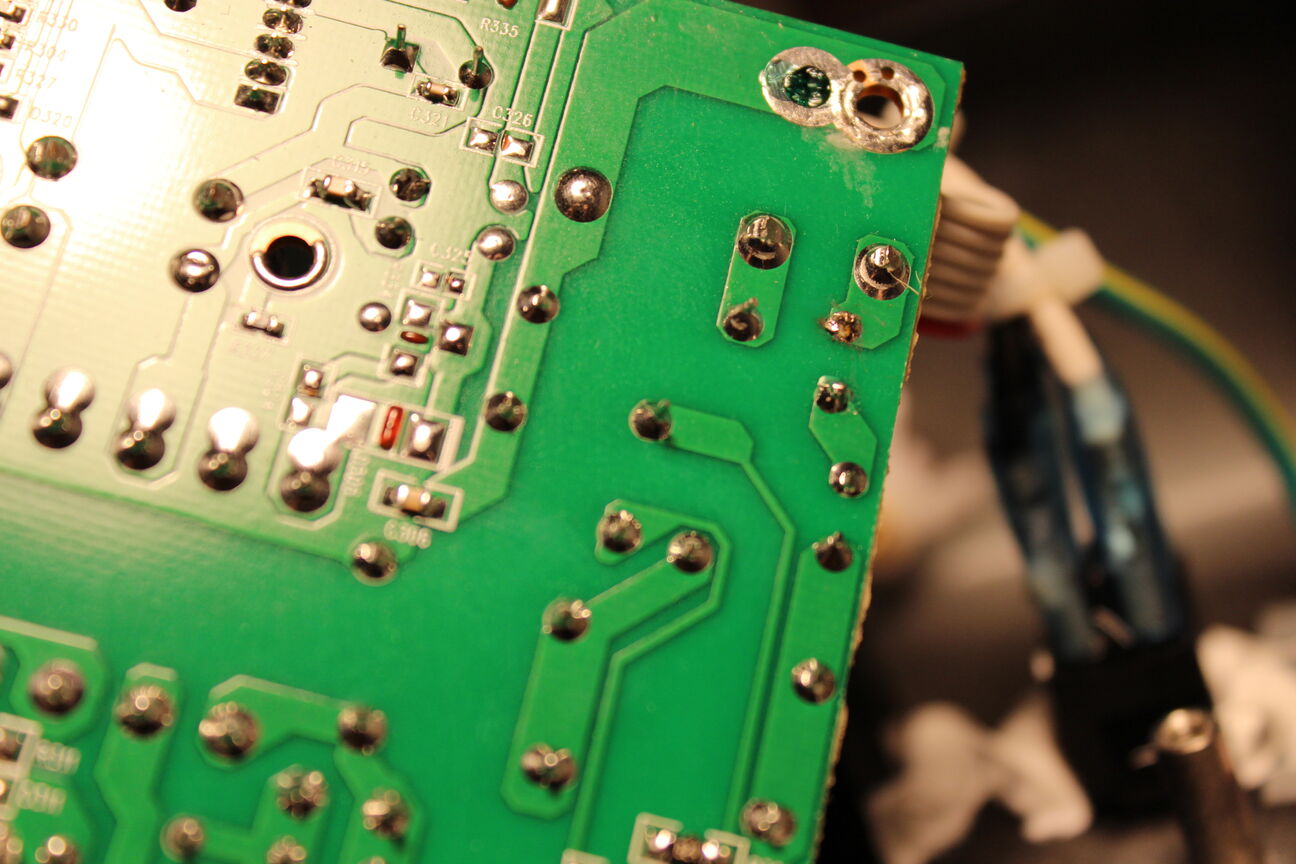

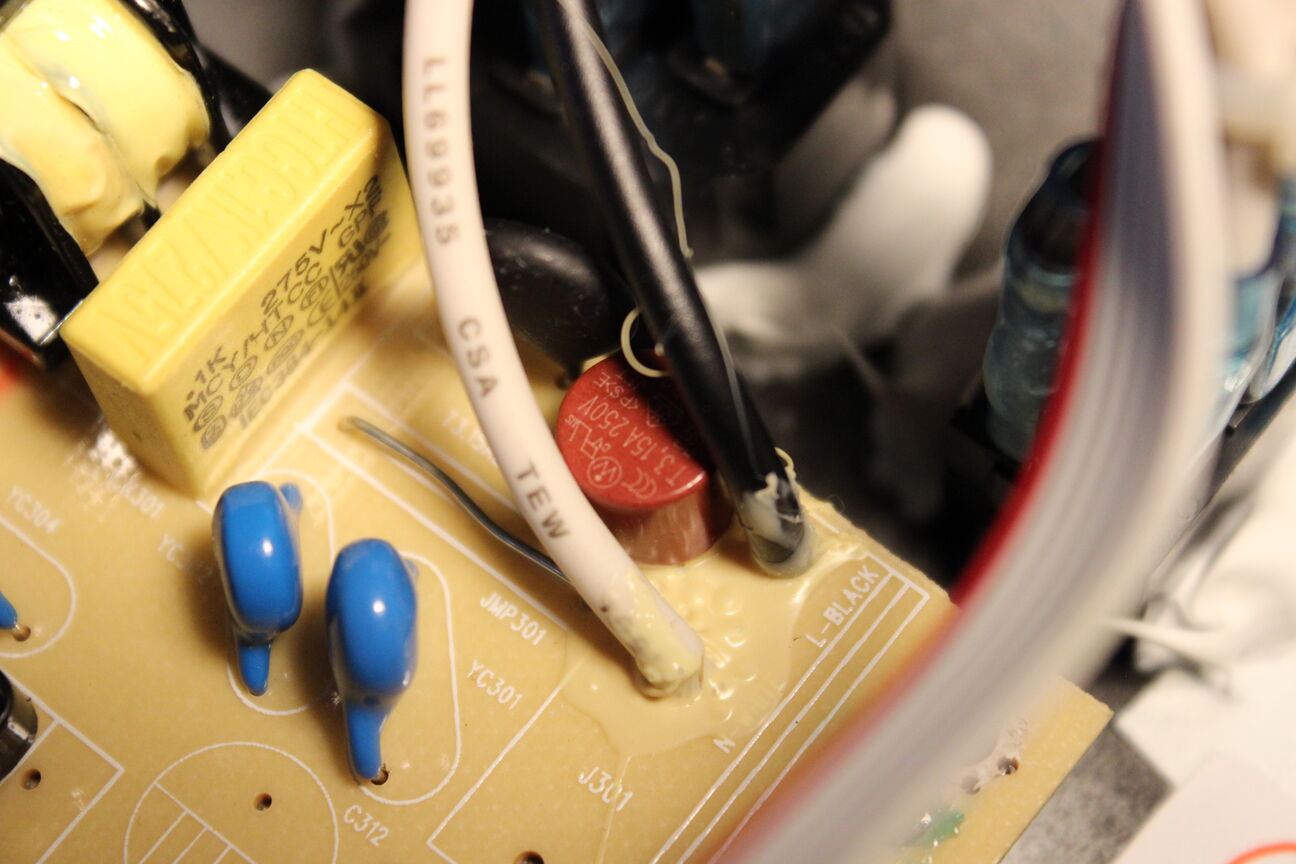

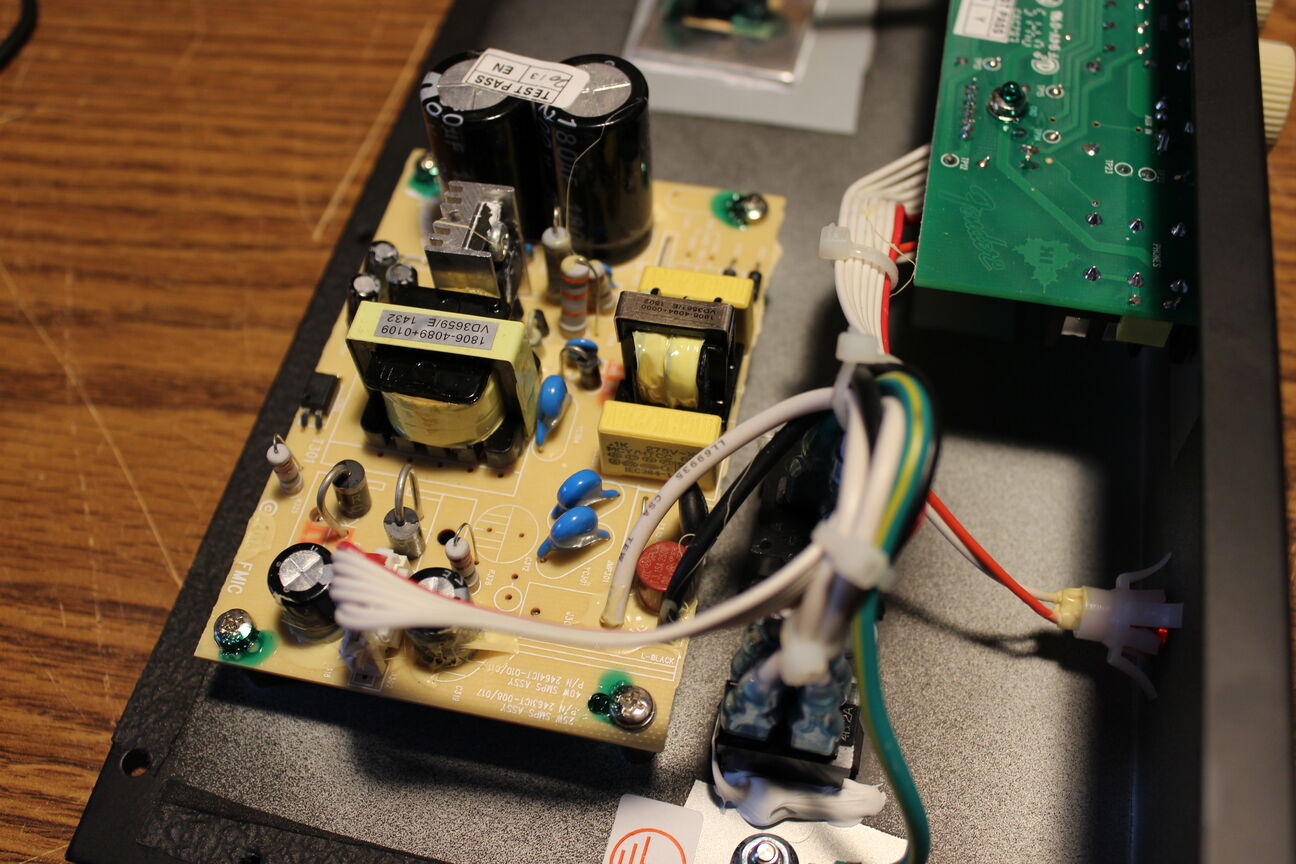

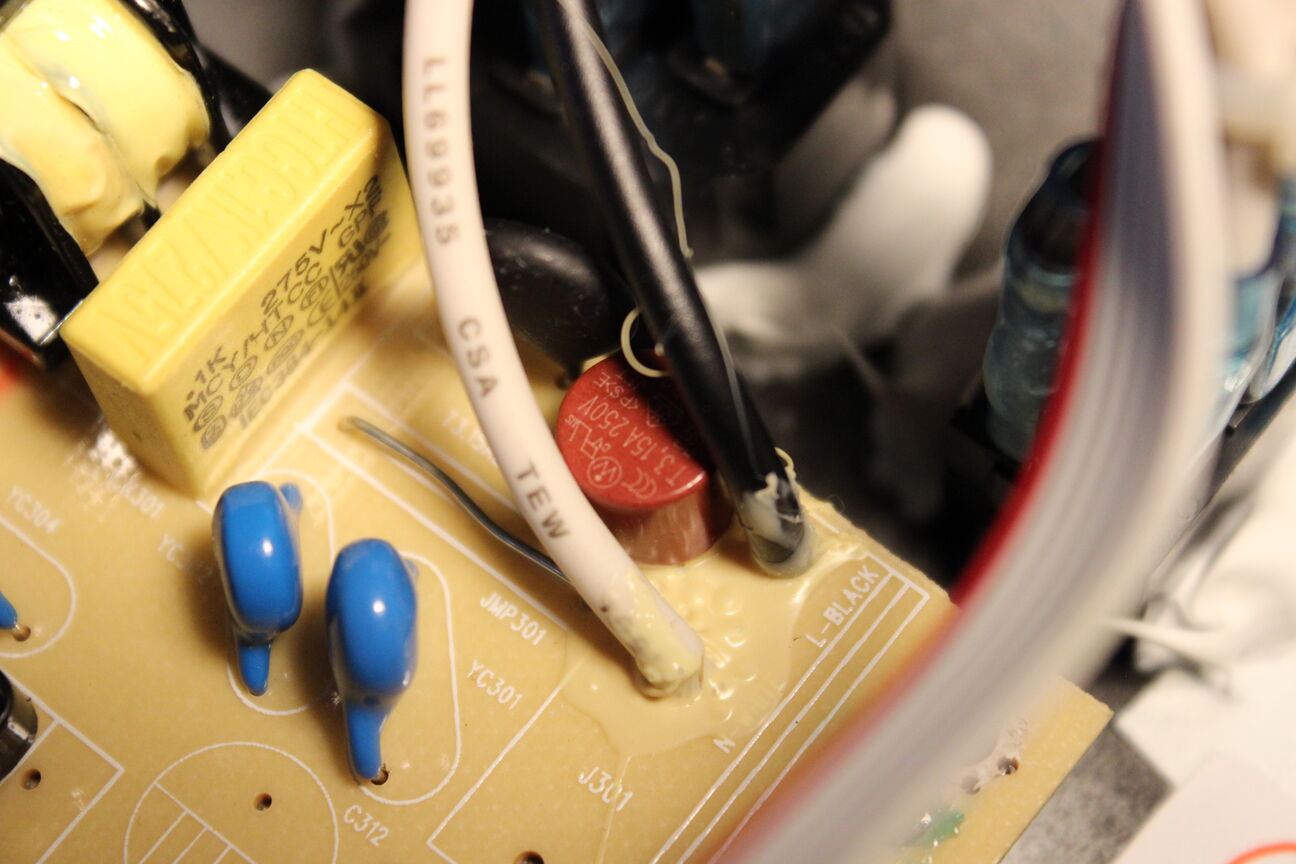

Not finding anything visually, I removed the board to trace the power supply. Here is a shot of where the wall voltage connects to the board. The hot side passes through an inductor before reaching the primary of the power transformer.

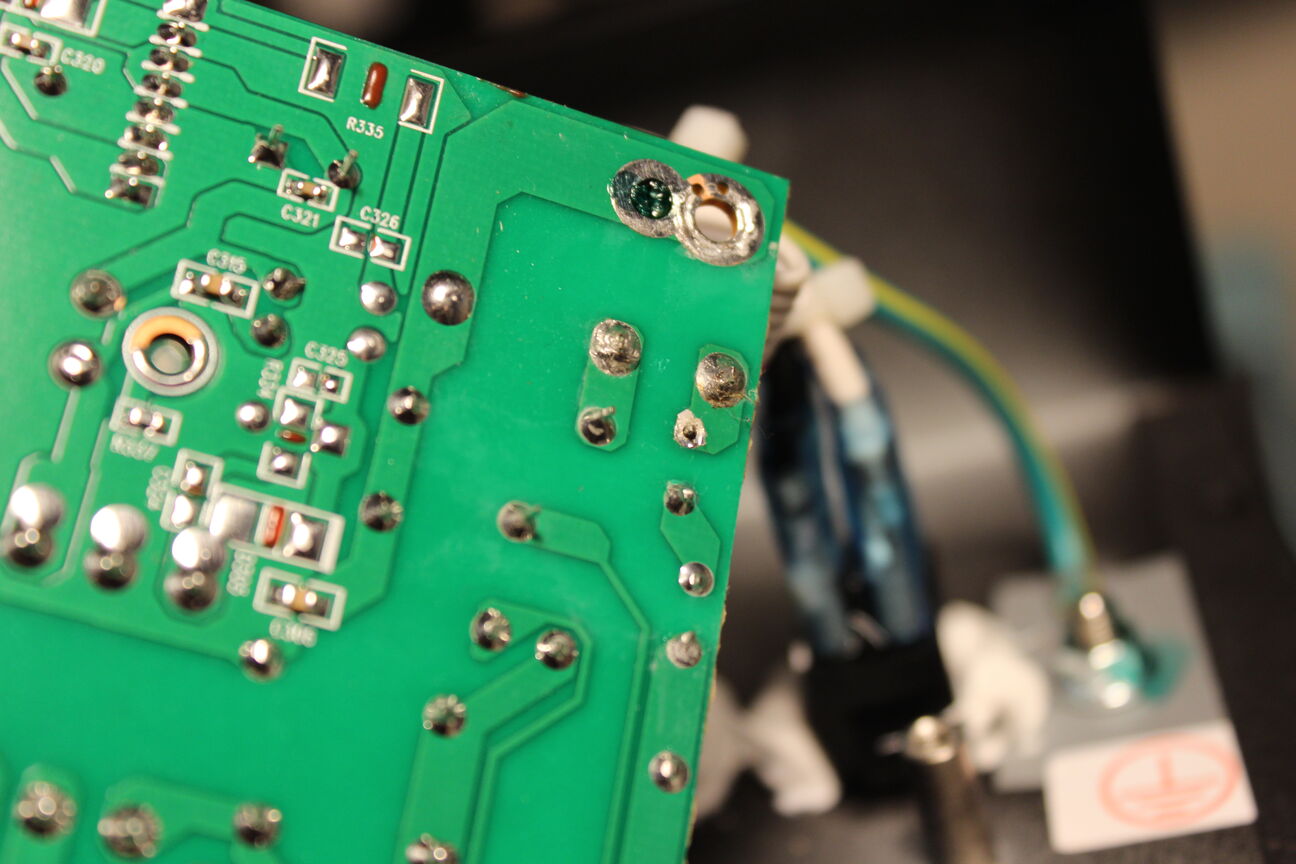

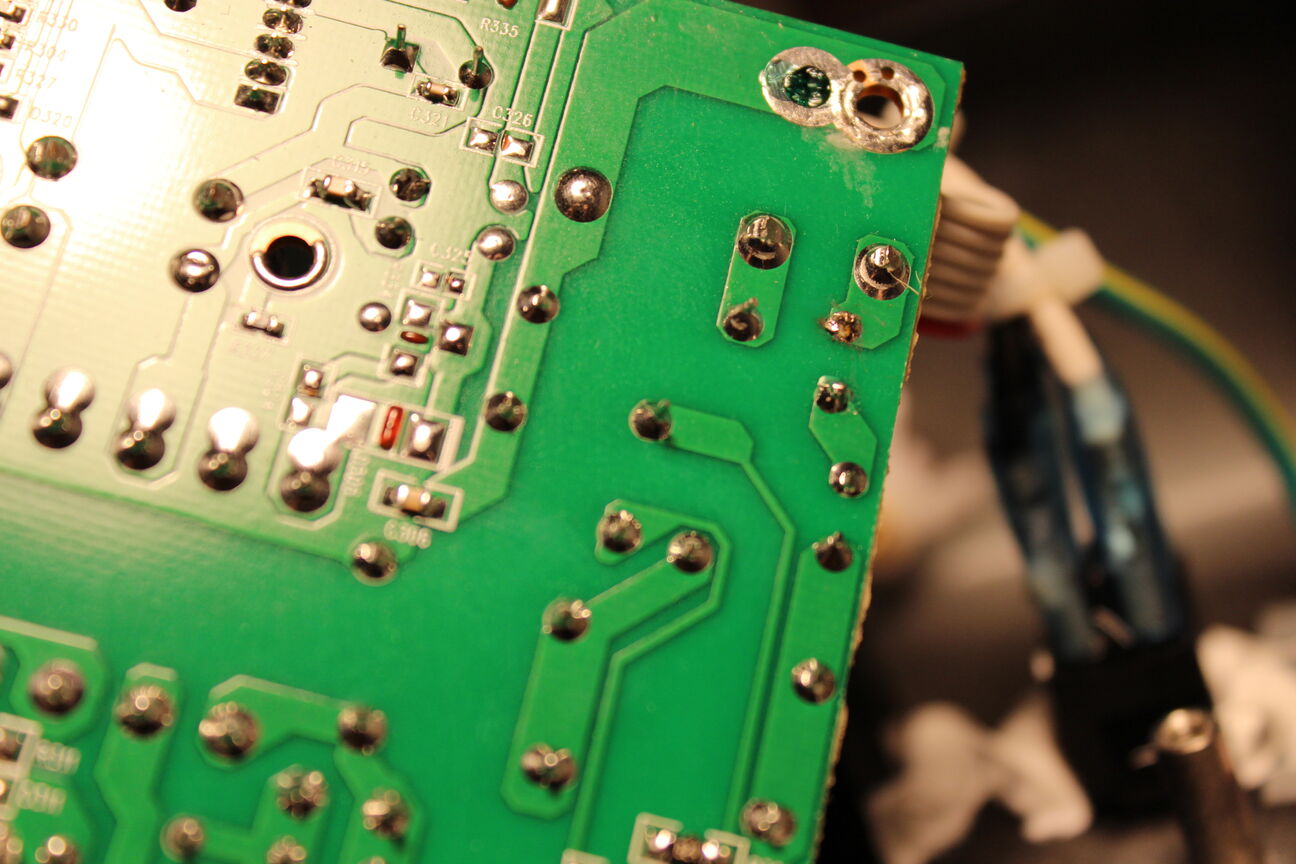

With the power on, I carefully probed the board starting at the AC input and when I reached the inductor with the probe, the amp turned on and the probe got stuck to the solder on the pad. That joint had gone cold and the multimeter lead caused an arc that fused the probe with the solder. I unplugged the amp and cleaned the remaining solder from the pad to check out its condition.

It looked good so I added some flux and fresh solder to the joint.

Here's a shot of the inductor that caused the problem.

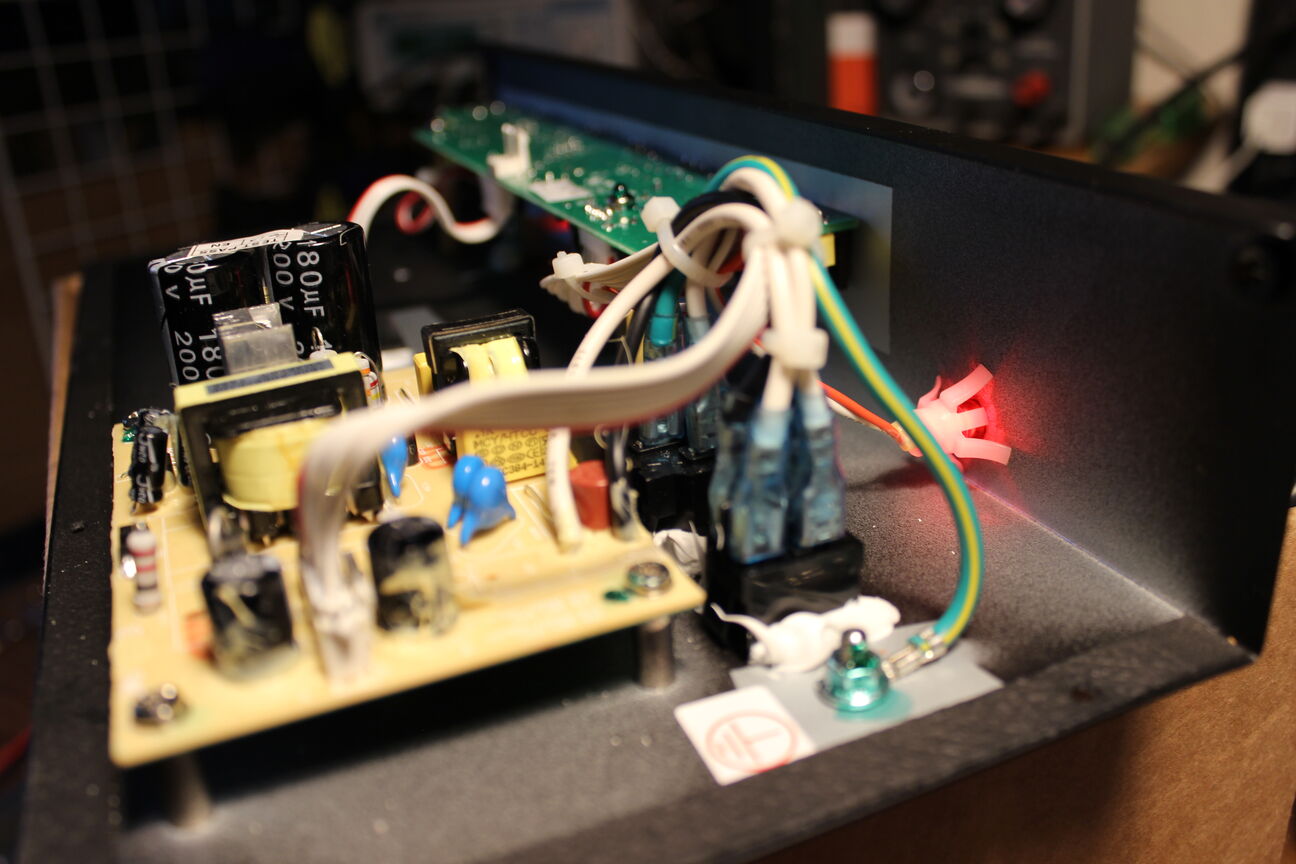

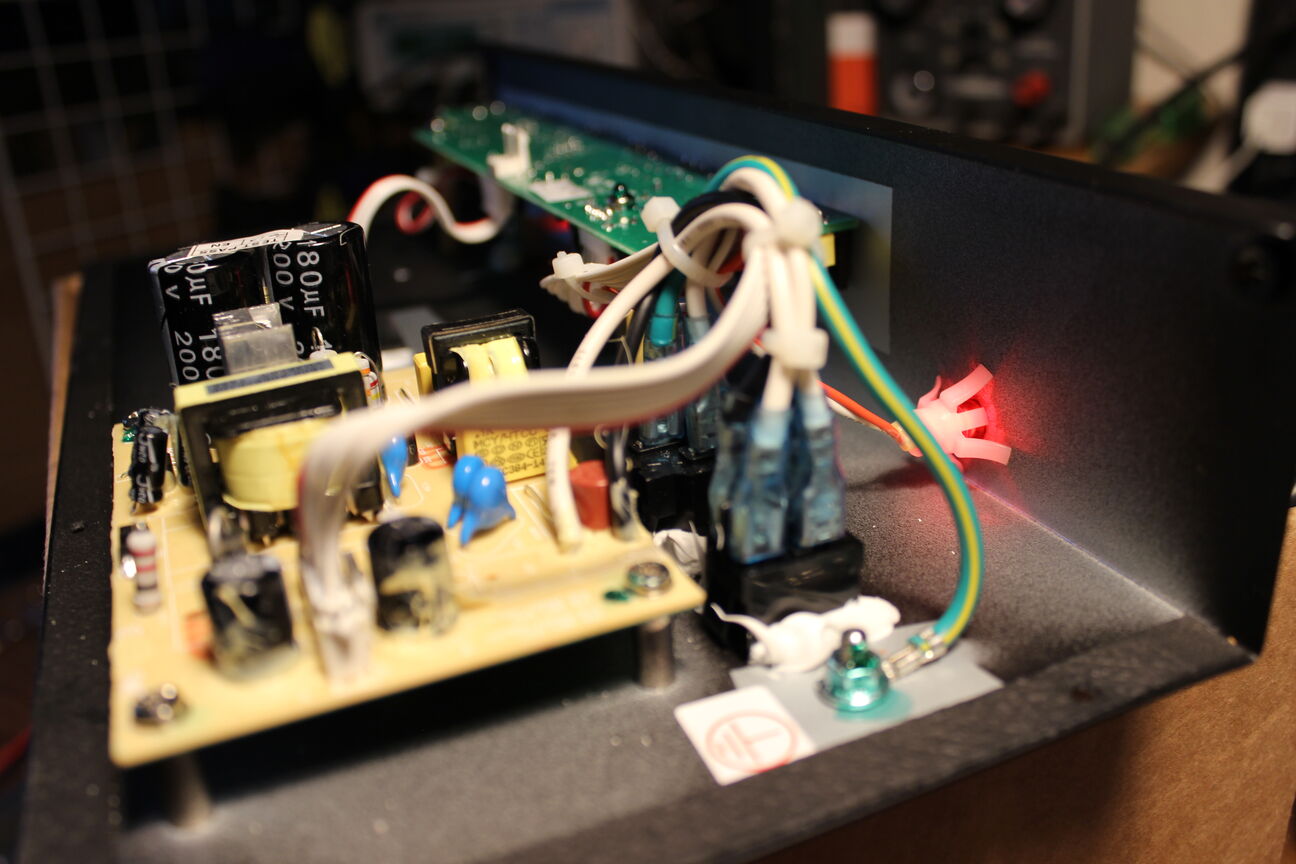

The amp was powering on again so I plugged in a speaker to check it out.

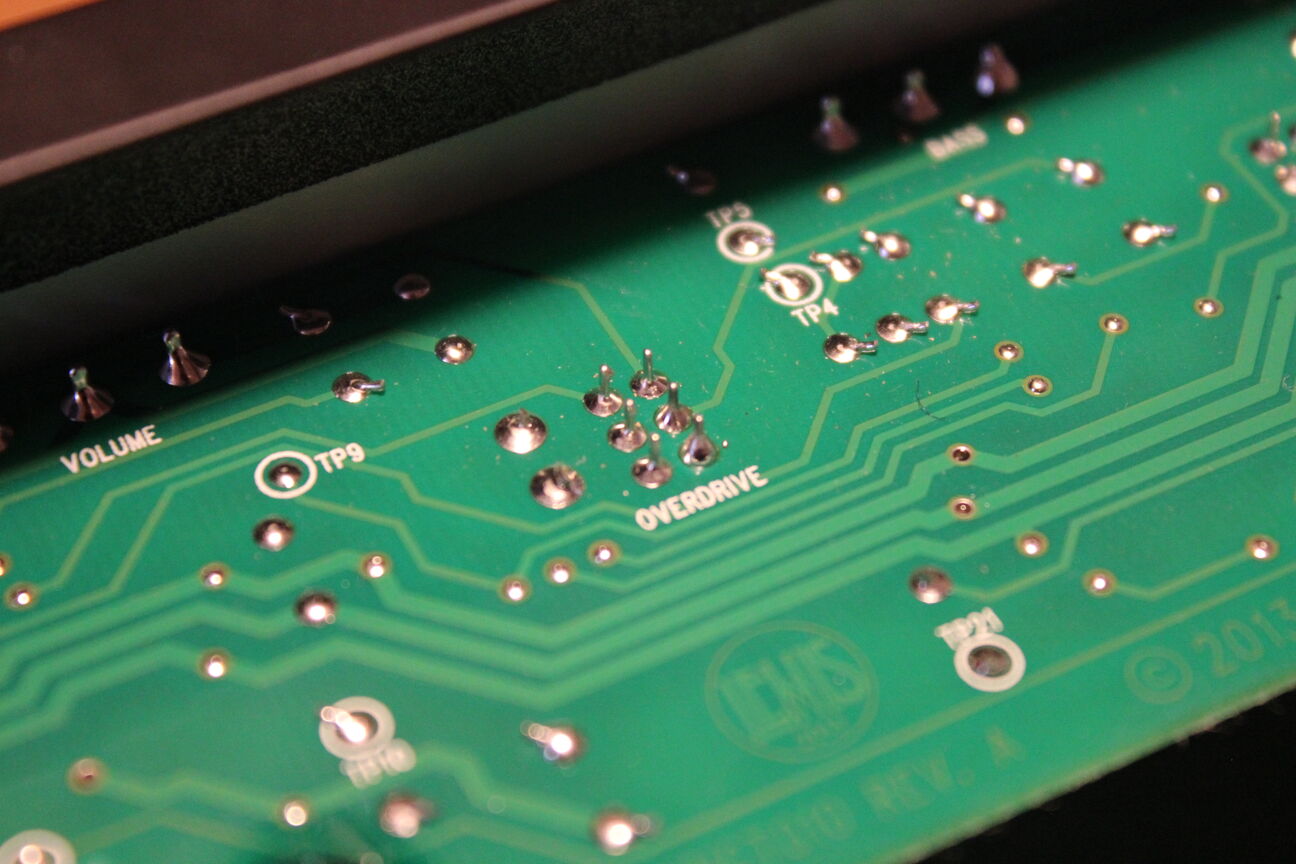

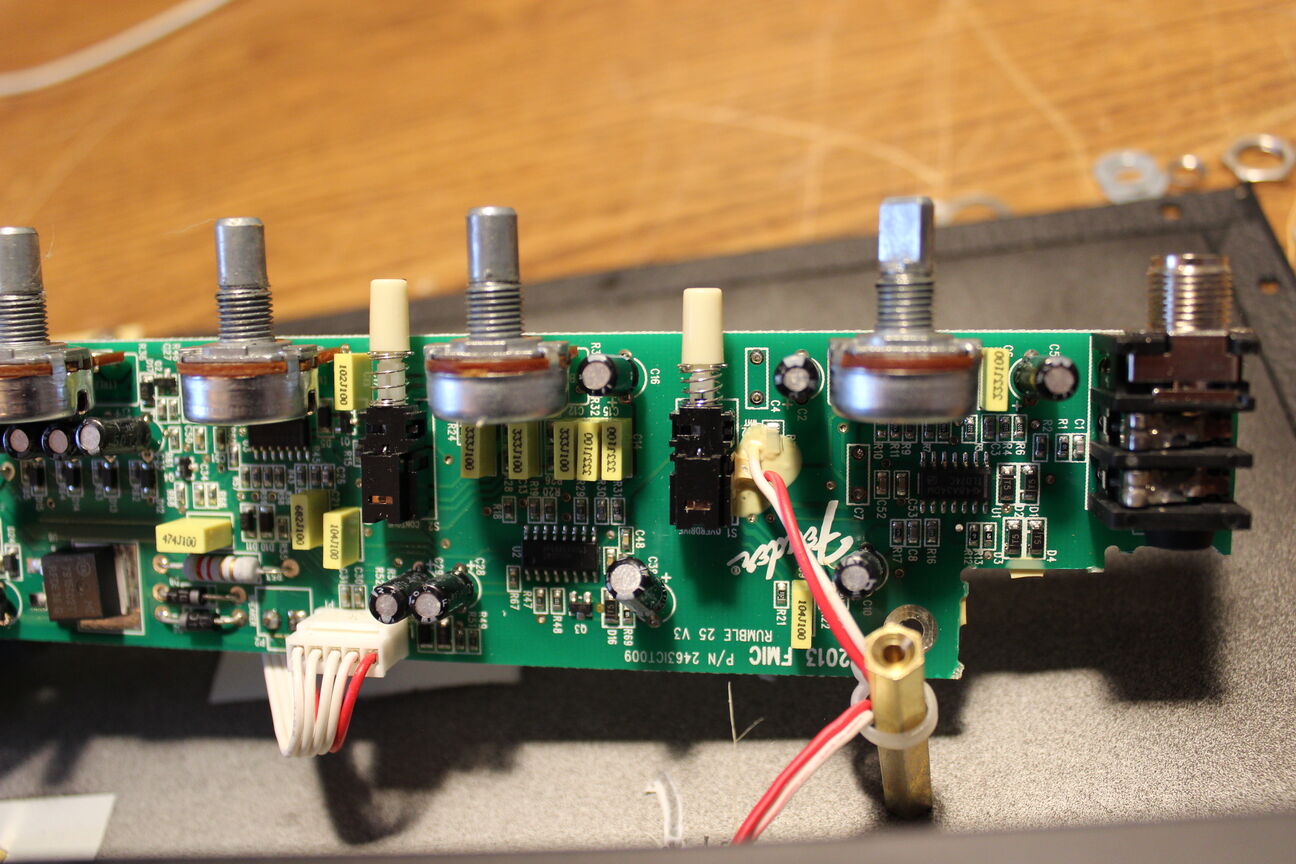

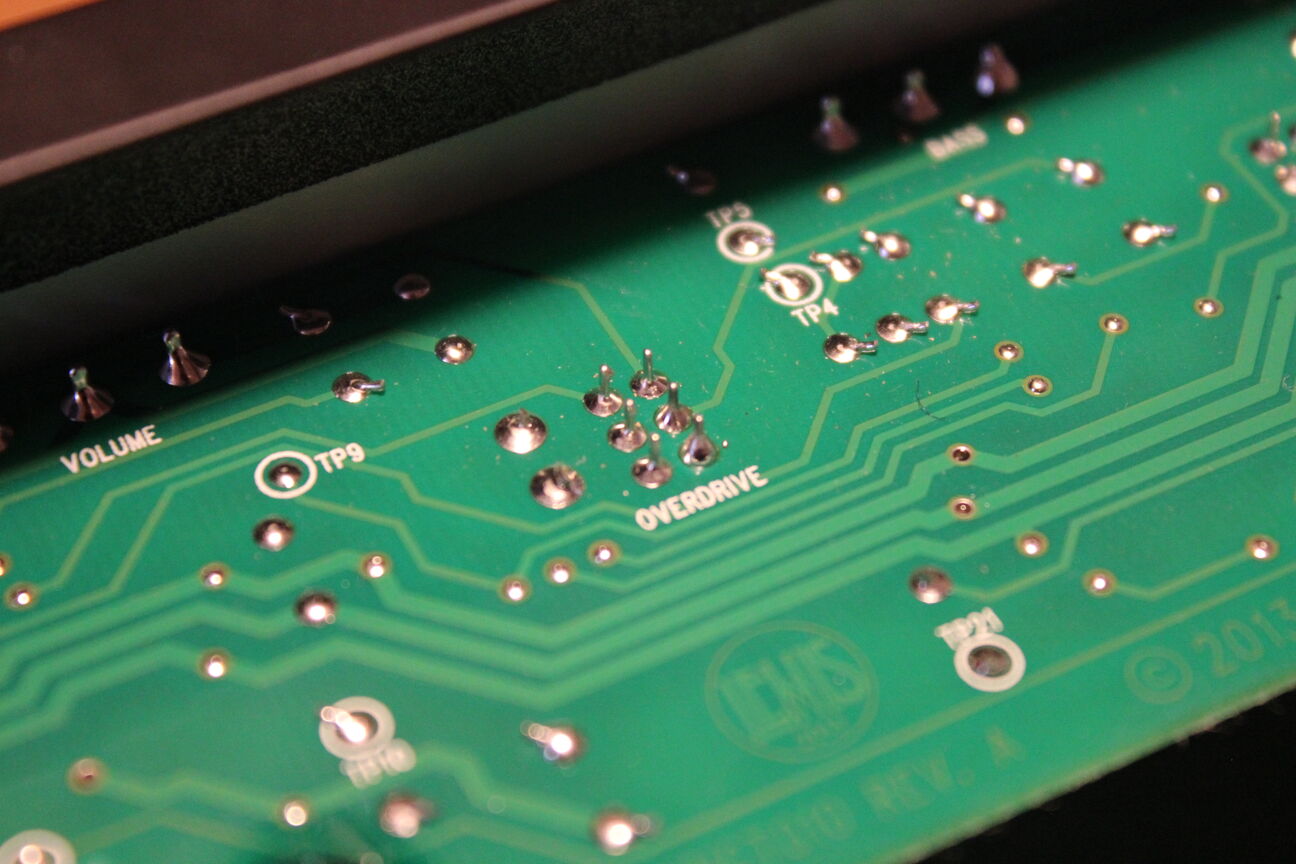

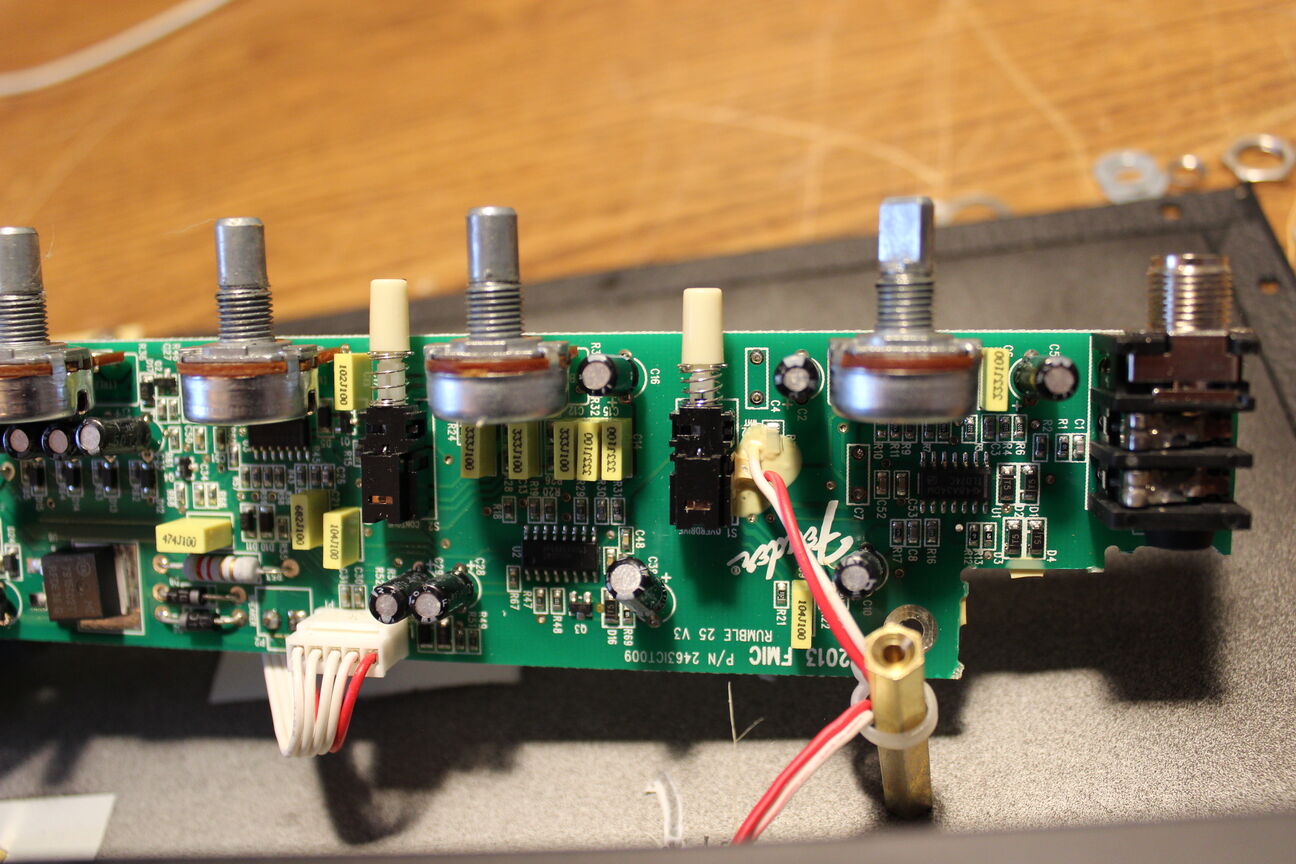

The amp sounded great with a bass until I pressed the overdrive switch. The sound cut out completely so I removed the amplifier board for a cleaning.

I cleaned all the switches and pots with contact cleaner and re-flowed the solder on the switches since they handle a lot of mechanical stress.

The switch problem was now gone and the amp sounded excellent so I reassembled and called it a day. I was surprised how loud this little amp could get.

First I checked the power supply board for any burnt looking components but everything looked normal.

First I checked the power supply board for any burnt looking components but everything looked normal.

Another shot of the board

Another shot of the board

Not finding anything visually, I removed the board to trace the power supply. Here is a shot of where the wall voltage connects to the board. The hot side passes through an inductor before reaching the primary of the power transformer.

Not finding anything visually, I removed the board to trace the power supply. Here is a shot of where the wall voltage connects to the board. The hot side passes through an inductor before reaching the primary of the power transformer.

With the power on, I carefully probed the board starting at the AC input and when I reached the inductor with the probe, the amp turned on and the probe got stuck to the solder on the pad. That joint had gone cold and the multimeter lead caused an arc that fused the probe with the solder. I unplugged the amp and cleaned the remaining solder from the pad to check out its condition.

With the power on, I carefully probed the board starting at the AC input and when I reached the inductor with the probe, the amp turned on and the probe got stuck to the solder on the pad. That joint had gone cold and the multimeter lead caused an arc that fused the probe with the solder. I unplugged the amp and cleaned the remaining solder from the pad to check out its condition.

It looked good so I added some flux and fresh solder to the joint.

It looked good so I added some flux and fresh solder to the joint.

Here's a shot of the inductor that caused the problem.

Here's a shot of the inductor that caused the problem.

The amp was powering on again so I plugged in a speaker to check it out.

The amp was powering on again so I plugged in a speaker to check it out.

The amp sounded great with a bass until I pressed the overdrive switch. The sound cut out completely so I removed the amplifier board for a cleaning.

The amp sounded great with a bass until I pressed the overdrive switch. The sound cut out completely so I removed the amplifier board for a cleaning.

I cleaned all the switches and pots with contact cleaner and re-flowed the solder on the switches since they handle a lot of mechanical stress.

I cleaned all the switches and pots with contact cleaner and re-flowed the solder on the switches since they handle a lot of mechanical stress.

The switch problem was now gone and the amp sounded excellent so I reassembled and called it a day. I was surprised how loud this little amp could get.

The switch problem was now gone and the amp sounded excellent so I reassembled and called it a day. I was surprised how loud this little amp could get.